1. Number of Components

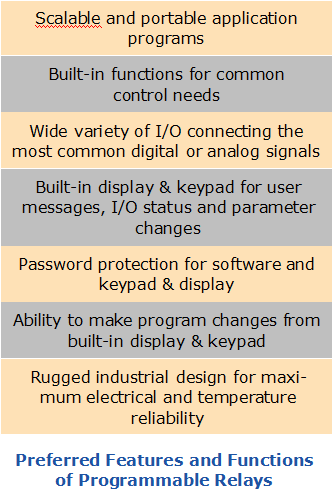

The basic design of a programmable relay integrates common control functions as built-in features to eliminate the purchase of separate control devices. Multiple timers, counters and cube relays can be replaced with a single programmable relay, greatly reducing the number of required components. This helps OEMs control costs and minimize component inventory levels and purchasing overhead.

2. Enclosure Size

The size of an enclosure required for multiple hardwired devices is much larger than that of a single programmable relay. The compact mechanical footprint of a programmable relay, with standard DIN rail or panel mounting clip options, significantly reduces the required electrical enclosure size. The size of an enclosure not only affects the individual enclosure cost, but more importantly the size of the machine and location to mount the enclosure.

3. Engineering and Configuration Effort

The programmable relay, as a single integrated and configurable device, greatly improves the OEM’s process of design and configuration. Easy to understand drawings can be developed quickly using provided CAD tem- plates from the programmable relay suppliers. Simple programming commands based on hardwired principles make configuring a programmable relay easy and eliminate the need for an engineer or trained programmer to configure it.

4. Manufacturing and Installation Cost

Assembly and testing of a system with hardwired controls requires a significant amount of interconnect wiring between individual devices, increasing material costs such as wire, terminal blocks, wire duct, DIN rail, etc., and labor costs. Installing and wiring a single programmable relay with a built-in power supply and screw terminals greatly reduces wiring time and testing with fewer connections and fewer possible points of failure.

5. Maintenance and Modification Support

A control system based on programmable relays helps an OEM reduce the amount of time for commissioning and maintenance. An integrated display and keypad on a programmable relay provides alarm messages and I/O status for easy troubleshooting, often eliminating the need for a multi-meter or logic probe, which is used to maintain hardwired controls. Customizing a programmable relay system to meet changing customer needs only requires programming changes without additional devices.

Broader application span: Extensive flexibility and simple programming language standards allow programmable relays to meet a wide variety of OEM product requirements.

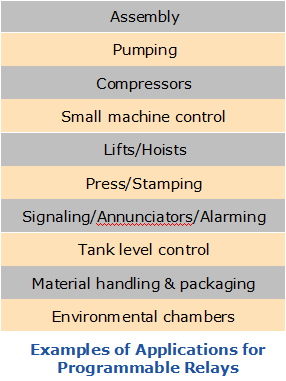

Broader application span: Extensive flexibility and simple programming language standards allow programmable relays to meet a wide variety of OEM product requirements. Use of programmable relays in the OEM market is growing rapidly. Over the past several years, OEMs have begun embracing programmable relays in a variety of applications as they continue to face challenges that require lower costs, greater functionality, and smaller product sizes, which has expanded the role of programmable relays beyond traditional markets.

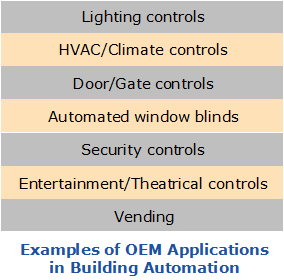

Use of programmable relays in the OEM market is growing rapidly. Over the past several years, OEMs have begun embracing programmable relays in a variety of applications as they continue to face challenges that require lower costs, greater functionality, and smaller product sizes, which has expanded the role of programmable relays beyond traditional markets. Lighting control by modern programmable relays provides building automation solutions for:

Lighting control by modern programmable relays provides building automation solutions for: